Designing and manufacturing of cams

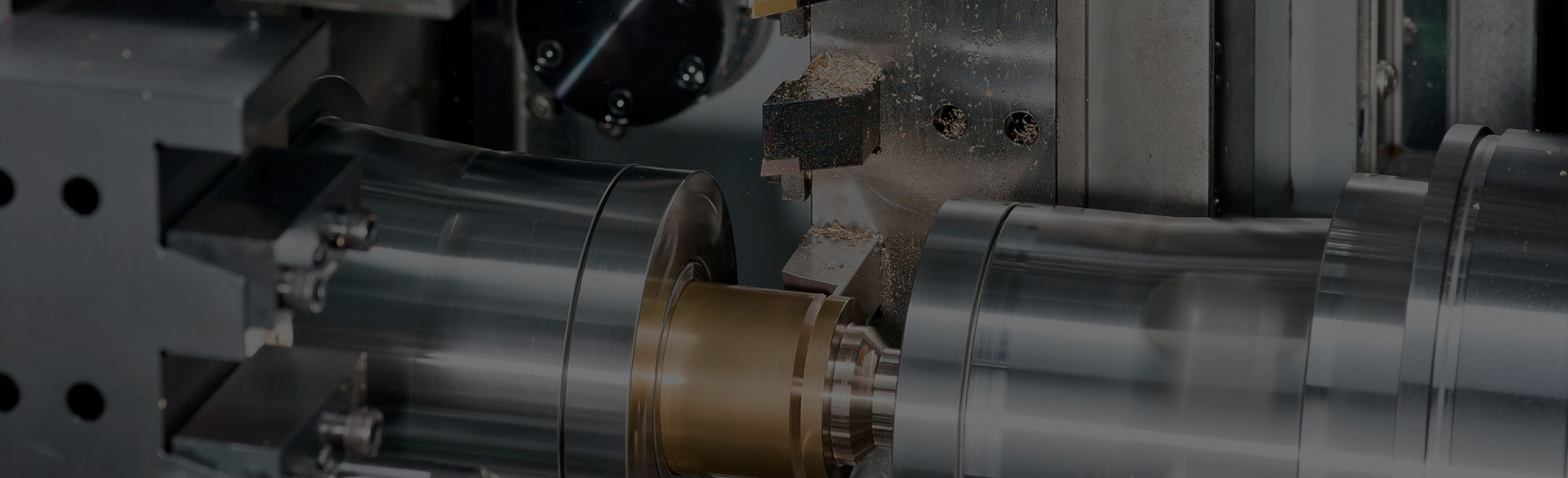

Cams play a crucial role in the securing and precision machining of workpieces on lathes and turning-milling machines. As integral parts of lathe chucks, they are highly functional. EA Engineering specializes in designing and manufacturing custom cams to meet the most exacting and specific production requirements. Our experience and professionalism allow us to create unique solutions that enhance efficiency and quality in machining processes.

What are custom cams?

The design and manufacturing process of cams at EA Engineering

Each project at EA Engineering begins with a thorough analysis of the individual client's requirements. This process allows us to precisely determine the necessary materials and machining technologies in order to create high-quality cams.

- Requirement analysis. Our engineers thoroughly study technical and functional characteristics of the clients' production, which helps identify key design parameters.

- Design development. Using advanced software, we develop detailed drawings that meet all standards and requirements.

- Prototyping. Before starting mass production, we manufacture samples for testing and approval to ensure that each cam meets the specified characteristics.

- Manufacturing. The manufacturing process involves the use of advanced technologies and high quality materials, ensuring the durability and reliability of each cam.

- Quality control. Strict control at each stage of production ensures that each cam completely meets the precision and strength requirements.

Optimized production

Examples of cam applications

Cams are widely used in both automatic and manual lathe chucks, where quick change of processed parts is required. They are ideal for batch production where every second counts. Due to their versatility, cams are an indispensable tool for machining parts in large volumes and ensure operational efficiency on the production floor.

Ordering and customization

Guarantees on products manufactured by EA Engineering

EA Engineering prides itself on our products fully meeting high industry and international quality standards. We adhere to the best practices in the manufacturing process and therefore regularly undergo audits and certifications.

Our commitment to the highest standards and quality forms the foundation of our interactions with clients. At EA Engineering, we place great value on your trust and satisfaction. We are ready to offer reliable and efficient solutions that support your production and contribute to its success.

Contact us

Contact us today to discuss your project and start working on a custom solution!

Fill in the form so we could solve your issue.